3D Printing: Clear Aligner Models

Significant Cost Savings, and Fast.

The field of digital dentistry has made significant advancements in orthodontic treatments, particularly with the development of clear aligners. Clear aligners, an innovative solution for correcting dental alignment issues, offer a discreet and efficient alternative to traditional braces. This knowledge-base article will explore the role of clear aligners in digital dentistry, their benefits, the manufacturing process, and the technologies involved.

Overview of Clear Aligners

Clear aligners are transparent, plastic forms of dental braces used to adjust teeth. They are custom-fabricated to fit each patient's mouth and designed to make incremental adjustments to the teeth's positioning over time. The aligners are virtually invisible and can be removed for eating, brushing, and flossing, offering a significant aesthetic advantage over metal braces.

Benefits of Clear Aligners

Aesthetic and Comfort

- Invisibility: Clear aligners are less noticeable than traditional braces.

- Comfort: With no metal parts, clear aligners are generally more comfortable.

Hygiene and Convenience

- Removable: Patients can remove aligners during meals and dental care routines.

- Reduced Chair Time: Fewer dentist visits are required for adjustments.

Customisation and Precision

- Tailored Treatment: Each aligner is custom-designed using 3D imaging techniques.

- Predictable Results: Advanced imaging and planning software provide precise control over teeth movement.

Digital Workflow in Clear Aligner Manufacturing

Digital ScanningThe process begins with a digital scan of the patient’s teeth using intraoral scanners. This scan creates a highly accurate 3D model of the patient's dentition, eliminating the need for traditional dental impressions, which can be uncomfortable and less precise. |

|

Treatment PlanningUsing specialised software, dental professionals can simulate the stages of teeth movements required to achieve the desired alignment. This digital planning allows for precise control and adjustment of each tooth's movement throughout the treatment plan. |

|

3D Print & ProcessingOnce the treatment plan is established, each stage of the aligner series is produced using 3D printing technology. SprintRay’s 3D printers, such as the Pro S and Pro95, are commonly used for this purpose. These printers are capable of producing aligners directly from the resin, making the process quick and efficient. Post-ProcessingAfter printing, the aligners undergo a post-processing phase, which includes washing, curing, and polishing to ensure they are smooth and clear. This step is crucial for patient comfort and the effectiveness of the treatment. |

|

Aligner FabricationAligner fabrication is done by thermoforming a plastic sheet on a printed model. This step is very similar to traditional aligner fabrication, where you used to thermoform an aligner sheet on the stone model, followed by trimming and finishing. |

|

Technology in Clear Aligner Production

Intraoral Scanners

Intraoral scanners replace the need for traditional dental moulds. These devices provide detailed and accurate dental scans in a non-invasive manner.

3D Printing Technology

3D printing has revolutionised clear aligner production by allowing for rapid, on-site manufacturing of custom dental devices. The technology ensures a precise fit and faster turnaround times.

Software for Treatment Planning

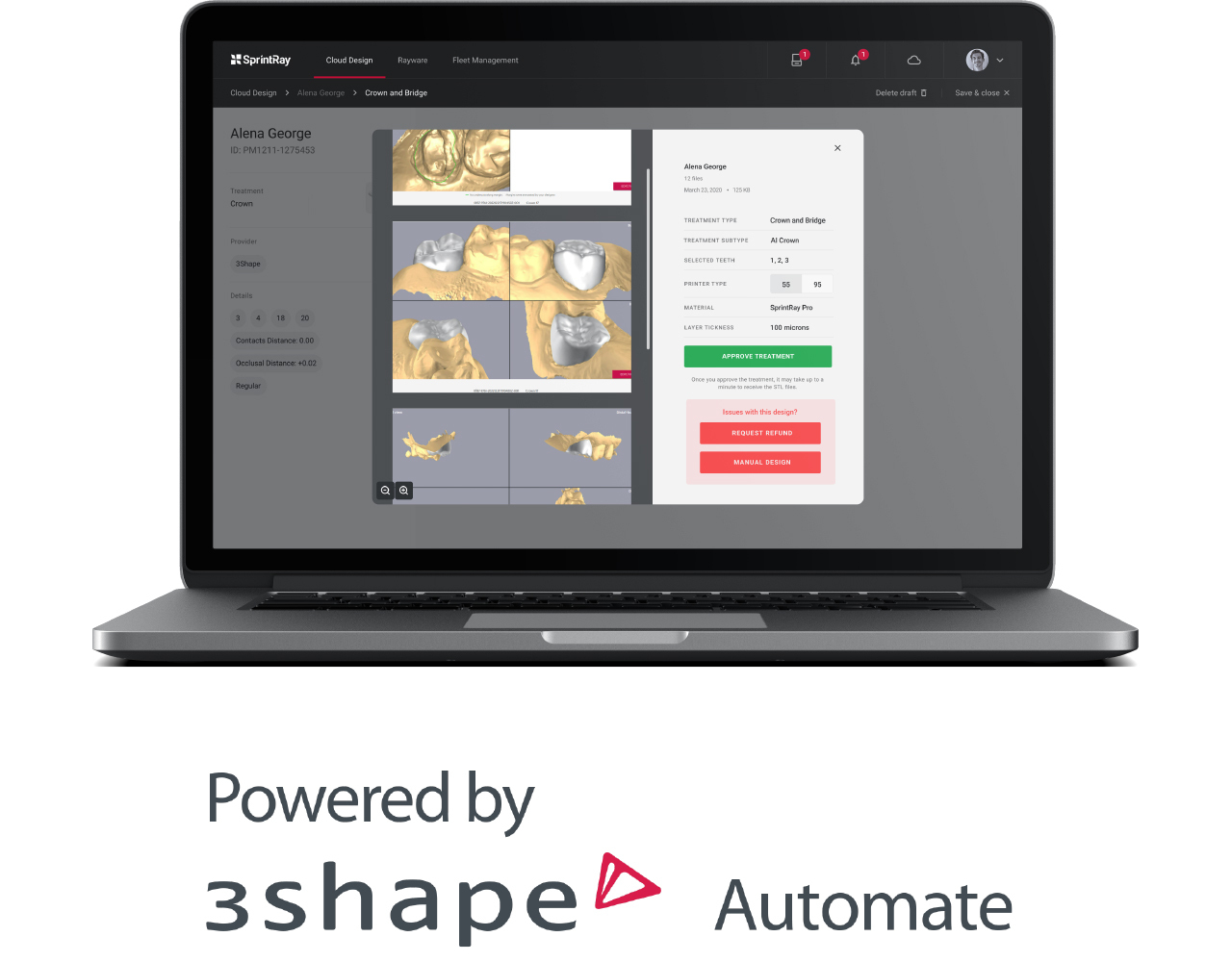

Software tools such as RayWare allow clinicians to plan, simulate, and execute clear aligner treatments with high accuracy. These programmes provide a step-by-step guide for the progression of teeth movement, ensuring optimal results.

Materials

The workflow presented here takes advantage of the SprintRay Die and Model 2 printing material.

SprintRay Die & Model 2 introduces significant advancements in dental modeling with its new grey color providing high contrast to enhance detail visibility. This resin minimises pigment settling, allowing more time for printing and less for mixing. It also boasts improved adhesion to the build plate and increased flexural strength, reducing breakage and enhancing success rates. With less odour and an optimized colour tone, Die & Model 2 Gray facilitates easier and faster digital restorations, improving the 3D printing experience in dental practices.

Clear aligners represent a significant advancement in orthodontic treatment, providing a comfortable, discreet, and efficient option for patients. The integration of digital scanning, 3D printing, and advanced software has transformed the landscape of dental care, offering precise and predictable dental corrections. As technology evolves, the adoption of clear aligners is likely to grow, making it an essential component of modern dental practices focused on cosmetic and orthodontic solutions.

Further information:

For reference materials, and for further detail on any of the SprintRay products and workflows, reach out to our friendly team.