3D Printing: Nightguards, Overnight

Significant reductions in production time.

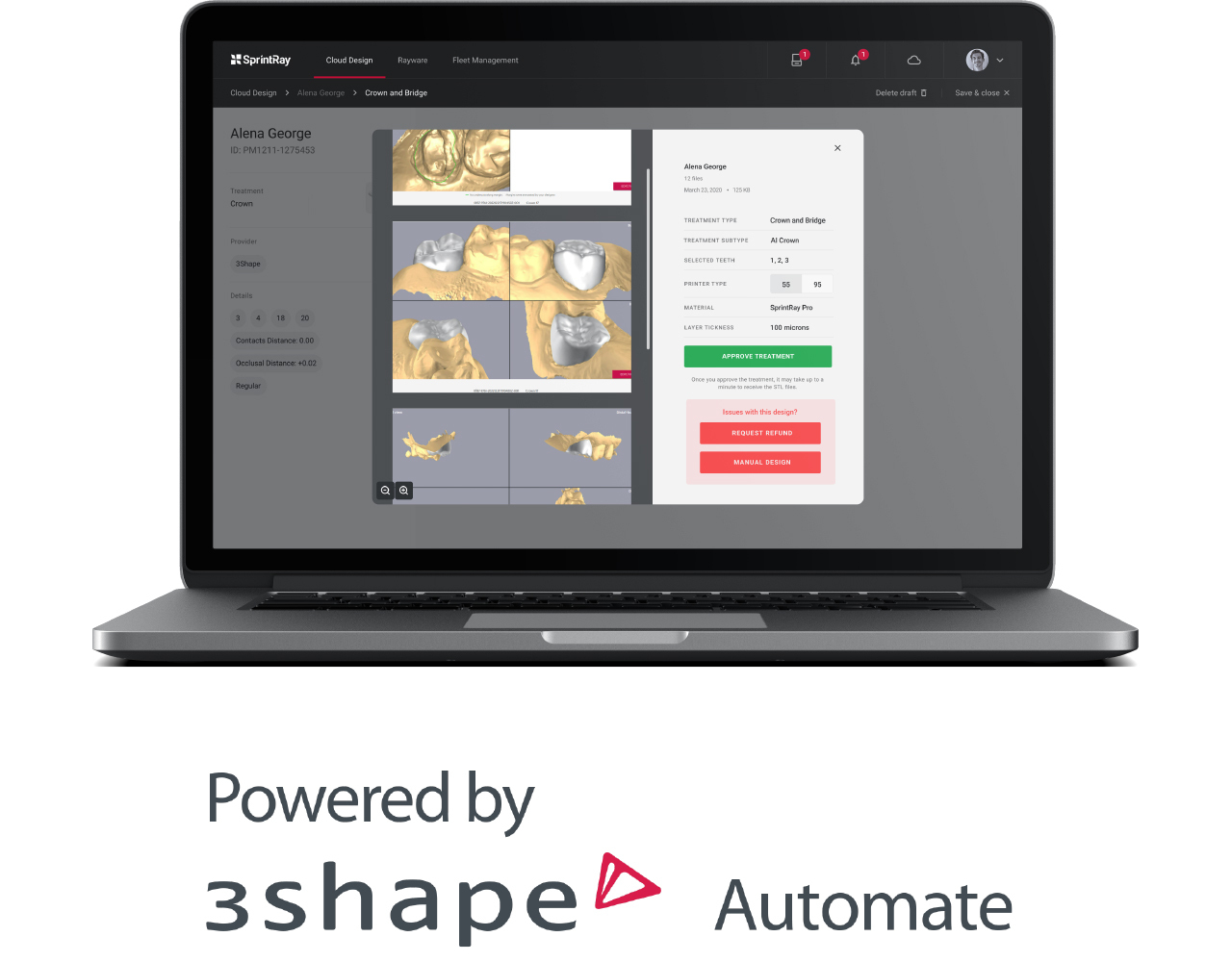

Streamline the fabrication of dental night guards by integrating scanning, artificial intelligence (AI) for design, 3D printing technologies, and straightforward post-processing methods.

This process significantly reduces production time, making it possible to complete a night guard in under an hour. Additionally, the use of advanced materials that adjust to body temperature for comfort and a simplified design approach without the need for CAD (Computer-Aided Design) software makes this an affordable and efficient option for dental care professionals. This method not only ensures a high degree of customisation and repeatability but also presents an opportunity for dental practices to enhance their service offerings in a cost-effective manner.

An Approachable Flow to Nightguard Fabrication:

ScanOne-click Scanner Integration. Take upper and lower scans with bite relation, then send them to SprintRay with a single click. |

|

Submit a Treatment5 Minute AI Design / 24hr Human Design Upload scans to SprintRay Cloud Design. Use NightGuard AI to receive a printable guard in 5 minutes or less, or overnight with Signature Design service. |

|

3D Print and ProcessEnd-to-end Printing Workflow. Send design files directly to your printer for fabrication. |

|

Available Designs:

- Flat Occlusal Guard

- Occlusal Guard with Anterior Ramp

- Michigan Splint

- Kois Nightguard

- Occlusal Guard without Anterior Coverage

Two Options for Outsourced NightGuard Design

NZ Dentists have two options for outsourcing the design of dental night guards: AI Design, which uses artificial intelligence for a rapid 5-minute design process based on patient scans, accommodating various dental conditions without CAD software; and Signature Design, which involves human designers using CAD to tailor the appliance specifically to the patient's needs within 24 hours, offering a bespoke service with the capability to address complex cases and patient-specific requirements.

1. AI Design

SprintRay AI systems automatically create a design based on your scans, accommodating a wide variety of patient needs - no CAD required.

- 5 min design: Submit patient scans and get a printable design in 5 minutes with the AI system

- Upper or lower: Both upper and lower guard designs available

- Bite agnostic: The AI system can design for closed or open bite scans to match your patient’s needs

2. Signature Design

Upload scans and let their designers handle the CAD. They'll provide a custom appliance to match the needs of your patient.

- 24 hr turnaround: Submit scans and instructions, then let our designers create a custom night guard

- Tailored care: The cloud design team can handle any request - from serious bruxers to patients with missing teeth

- Bespoke service: Communicate with the designer and revise the design until everything is just right

Materials

The workflow presented here takes advantage of the SprintRay NightGuard2 printing material.

The NightGuard Flex 2 represents an evolution from its predecessor, enhancing durability and introducing a desired clear variant. This iteration exhibits high fracture resistance and can be polished to a high transparency, mirroring the quality of laboratory-crafted occlusal guards.

It's designed to become flexible at body temperature, ensuring patient comfort while simplifying adjustments and delivery in a dental setting. The Biomaterial Innovation lab's advancements in resin technology have culminated in this professional-grade material, aimed at long-term oral protection.

Further information:

For reference materials, and for further detail on any of the SprintRay products and workflows, reach out to our friendly team.