3D Printing: Ceramic 3D Printed Crowns

Cost-effective posterior crowns in less than an hour.

SprintRay's Ceramic Crown Solution introduces a comprehensive approach to the chairside fabrication of ceramic crowns, streamlining the process from scanning to delivery within approximately 45 minutes. This workflow integrates three pioneering elements: automated AI-powered design software, a novel ceramic-dominant resin, and advanced production hardware.

To assure reliability and effectiveness, extensive scientific research and clinical evaluations have been conducted, confirming its suitability for use in dental practices.

The Ceramic Crown Solution:

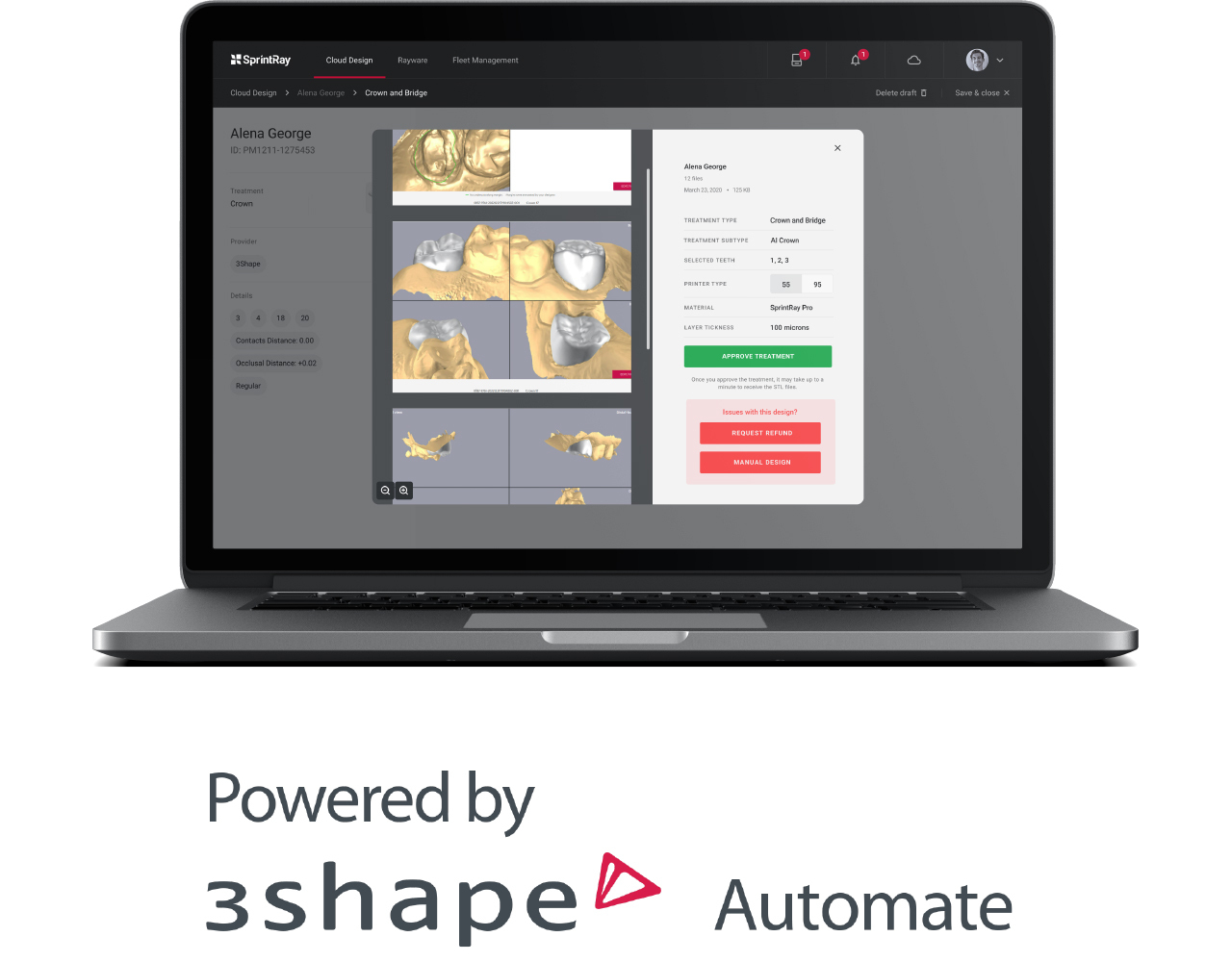

AI-Powered Crown Design TechnologySprintRay Cloud Design leverages artificial intelligence to streamline the crown design process, offering an automated and efficient solution. This technology facilitates rapid turnaround times for posterior crown designs, enabling the provision of single-visit restorative dentistry services. |

|

The Pro S Crown KitThe Pro S Crown Kit is an add-on for SprintRay S 3D Printers. It features an innovative compact build platform and resin tank, specifically designed to enhance the production efficiency, capable of fabricating up to six single-unit crowns within approximately 10 minutes. |

|

Ceramic Crown ResinThe Ceramic Crown Resin transcends traditional hybrid ceramic materials by offering a ceramic-dominant composition that is definitive and designed for use in full crowns, partial crowns, and veneers. This material sets a new benchmark in premium aesthetics, exceptional strength, and customized comfort. The SprintRay Ceramic Crown Solution allows for the production of a definitive crown in a minimal timeframe of about 10 minutes, at an approximate cost of $12 (NZD). |

|

SprintRay ProCure 2ProCure 2 significantly enhances the efficiency of post-curing processes, potentially reducing times by up to tenfold, which facilitates the integration of chairside 3D printing in dental practices. It achieves this with a custom curing engine that delivers 25 times more light power, enabling the curing of a night guard in only three minutes without the need for preheating. Equipped with an intuitive, cloud-connected touchscreen interface, ProCure 2 simplifies the operation of chairside 3D printing, making it accessible with just a single button press. |

|

The Workflow:

1. Scan

Use any scanner to capture the post-prep anatomy of your patient. SprintRay has partnerships with major scanner brands, but the ecosystem accepts files from any manufacturer.

2. Design

We are Powered by 3Shape Automate to bring you the fastest, most reliable AI design on the planet. Upload your scan files and get a posterior crown design in 5 minutes or less.

3. 3D Print

With the Pro S Crown Kit, you can 3D print ceramic crowns in as little as 10 minutes without sacrificing the anatomical detail or aesthetics of the restoration.

4. Wash & Cure

Submerge the ceramic crown in a small bowl of IPA, then brush to remove all residue. Dry the part with compressed air and a clean paper towel. Place it in ProCure 2, and select the ‘Ceramic Crown’ curing profile.

5. Wash & Characterise

Submerge the ceramic crown in a small bowl of IPA, then brush to remove all residue. Dry the part with compressed air and a clean paper towel. Ceramic Crown can be characterized and glazed using common glaze kits or polished to the patient’s aesthetic needs with a lab handpiece and a lathe.

6. Delivery

Use an adhesive, followed by a resin-based. cement for luting the crown to the prepped tooth. Sand-blasting the intaglio surface of the crown before using the adhesive is highly recommended

The Studies

Renowned institutions around the world have investigated the mechanical characteristics and effectiveness of Ceramic Crowns for definitive restoration. The Division of Biomaterials at the University of Alabama at Birmingham, SD Mechatronik, and the SprintRay Materials team conducted tests on Ceramic Crowns in various studies:

• Fracture Load and Abrasion Resistance

• Occlusal Wall Thickness Effect on Fracture Load

• Chewing Simulation Abrasion Resistance

• Bonding Strength with Luting Composite

• Shear Bond Strength Luting Workflow Comparison

For reference materials on these studies, and for further detail on any of the SprintRay products and workflows, reach out to our friendly team.